Can You Sublimate on Stainless Steel

Do you want to know that can you sublimate on stainless steel? All of the information you require is provided. Read on.

If you want your morning stainless steel cup to look different, you can sublimate it with the right tools to make art that is both flexible and bright. But you need to know what kind of steel surfaces are needed to keep the sublimation ink in place before you start sublimating on stainless steel.

Yes, you can sublimate on stainless steel, but it requires a special sublimation coating. The coating allows the sublimation ink to adhere properly to the surface. Without this coating, the sublimation process will not work effectively on stainless steel.

This article will also discuss if can you sublimate on stainless steel the advantages, procedures, and optimal approaches to sublimating onto stainless steel.

Discover which surfaces produce the best results and how to properly prepare them for printing.

Additionally, we shall address typical challenges that might emerge throughout the sublimation procedure.

Explore the complex and demanding world of sublimation on stainless steel with us.

Related Post: Can You On Sublimate Glass

Key Takeaways:

- It is possible to sublimate on stainless steel, but a special sublimation coating is necessary for the ink to adhere properly.

- Sublimation on stainless steel creates durable, vibrant images that are resistant to fading, scratching, and peeling, making it ideal for both indoor and outdoor use.

- Proper surface preparation, including cleaning and potentially applying a special coating, is crucial for achieving the best sublimation results on stainless steel.

- Sublimation requires a compatible printer, sublimation ink, transfer paper, and a heat press or convection oven to transfer the image onto the stainless steel surface.

- Issues like uneven color distribution and image blurriness can be addressed by ensuring even heat and pressure, using high-resolution images, and properly securing the transfer paper during the sublimation process.

The Advantages of Sublimating Stainless Steel:

When sublimating on stainless steel, all of its benefits become clear, making it a great choice for making images that are bright and last a long time.

Direct transfer of dye onto a substrate is what sublimation methods do. This makes an image that lasts and is of high quality. Stainless steel’s long-lasting and rust-proof nature makes it a good material for sublimation.

This makes it possible for the patterns to last in harsh conditions and keep their shine over time.

One of the best things about sublimating on stainless steel is that it lasts a very long. It’s hard for the sublimated picture to fade, scratch, or peel off because it becomes part of the metal itself.

This makes sure that the design stays bright and whole, even after being used a lot and being exposed to outside elements.

In addition, flattened stainless steel is very good at blocking water and UV light. Because of this, it can be used both inside and outside, since the patterns stay clear and colorful even in harsh conditions.

When you sublimate on stainless steel, the results will last and look good for a long time. This is true for signs, artistic panels, and custom-made items.

Related Post: Can You Sublimate on Silicone?

Can I Sublimate On Stainless Steel?

Yes, You can easily sublimate on stainless steel. However, the substrate must have a polyester layer for the sublimation ink to stick to it. This is because sublimation ink likes to soak into the coat of hard substrates.

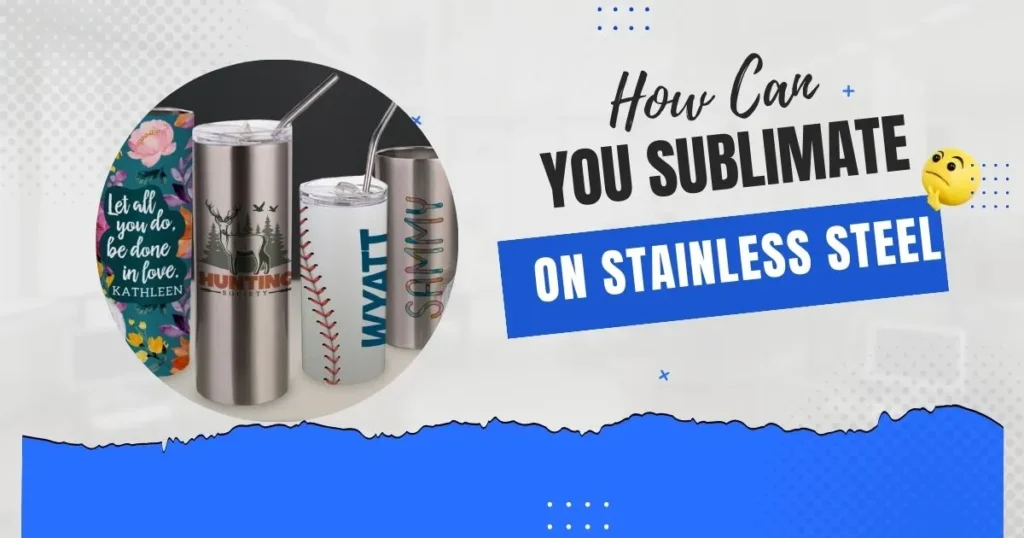

Besides that, there are two different ways to sublimate steel, which we fully explain in our post. If you want to sublimate a mug, tumbler, or water bottle, you need a mug or tumbler press. You can use a t-shirt heat press on flat things like stainless steel sheets and frames.

Related Post: Can You Sublimate On Burlap

Step By Step Guide On How Can You Sublimate On Stainless Steel:

Step 1) Prepare the Design Using Online Tools:

Measure the diameter and height of your substrate with inch tape before you start printing. Use online design tools like Photoshop or any other one you like to get that size ready.

Once the picture is uploaded, it needs to be prepared based on the material size.

Step 2) Mirror the Picture:

So that the printer knows how to print the picture, you need to flip the picture around if your design has letters or a unique picture in it.

The feature can be turned on in either the Cricut design space or the tools you’re using. In the printer settings, you can also change how the paper prints. Now is the time to print the picture.

Step 3) Stick the Printed Sublimation Paper Down With Tape:

After printing, use scissors to cut off all the extra-long sides, leaving a half-inch of extra-long sides so you can put the heat-resistant tape on them. It’s also possible to print and cut.

On the tumbler, place the printed sublimation paper so that the printing side is looking down and touching the surface of the tumbler. Put heat-resistant tape on both sides and then wrap the tumbler or mug in butcher paper and tape it down. This will keep it in place.

Step 4) Pressing the Substrate With Heat:

We’re ready to heat press now that the items have been wrapped. Now that the base is ready, let’s put it in the mug press. A Cricut Mug press lets you set the time and temperature without any trouble.

Setting the mug heat press to 400F for 60 seconds on each side of the base is what you need to do.

You can heat press the first side of the glass with the Cricut mug press for 30 seconds. Then you can turn it over and heat-press the other side.

Step 5) Take Away from the Heat Press:

Once the glass or mug is hot, take it out of the heat press wearing gloves that can handle the heat and let it cool down.

Now take off the tape that can withstand heat. It will be very clear if you use butcher paper and sublimation paper from the tumbler.

Related Post: Can You Sublimate on Cardstock

Method 2) Using the Convection Oven:

You don’t need a heat press, a sublimation printer, sublimation ink, or sublimation paper for this easy method. One thing is that you need a Cricut to make and cut the tool.

We’ll be using sublimation Cricut sheets that have already been made. When you use the Cricut infusible ink sheets, you can only make a certain number of designs.

- Use the Cricut design space to make a drawing, and make sure the image size is right for your substrate in the design space.

- Make sure to mirror the pattern if you’re making the letters, then start making it. You can also look for the printing material in Cricut Design Space by typing in Cricut infusible ink.

- After positioning the intended Cricut sheet onto the vinyl grip surface, proceed to cut the design by utilizing the cut function on the Cricut maker.

- Remove any weeds from the design and secure it with heat-resistant tape.

- Isolate the substrate by encircling the prepared mug in the Sublishrink material and employing a heat gun.

- Preheat the convection oven to 400 degrees for five minutes.

- After covering the substrates with paper and placing them for 5 minutes, remove the shrink.

- In the oven, your stainless steel sublimation printing is now complete.

Related Post: Can You Sublimate On Modal Fabric

Printers That Support Sublimation on Stainless Steel:

If you want to sublimate on stainless steel, you need to look into the printer choices that will work with it.

We need to think about whether the ink will work with sublimation and make sure that the printer settings are best for sublimation.

The Best Printers:

We have found the best printers for sublimating on stainless steel after doing a lot of study. The Epson SureColor P600 and the Sawgrass Virtuoso SG800 are the best printers for sublimation paper.

Both printers have a high print resolution and great color reproduction, so pictures on stainless steel will be bright and clear.

A heat press machine is needed to put the sublimated pictures on the stainless steel. The HIX Swingman 15 and the Geo Knight DK20S are both great choices.

With these tools, the heat is spread out evenly and consistently, so the right amount of heat and pressure can be used to make sublimated prints on stainless steel that last a long time.

With the right printer and a solid heat press, you can get sublimation prints on stainless steel that look like they were made by a professional.

Related Post: Can You Sublimate On Rayon

Compatible Sublimation Inks:

For the best results when sublimating on stainless steel, we suggest using machines that can handle sublimation ink. If you want to sublimate on stainless steel, you should make sure that the printer you choose works with sublimation ink so that the prints last and stay bright.

Here are four important things to think about:

Model of Printer:

Go with a printer that is made just for sublimation printing. These printers usually have features that let you use sublimation ink and make good prints.

Ink Compatibility:

To make sure the printer works with sublimation ink refills or bulk ink systems, make sure the ink is compatible. This kind of ink is designed to stick well to metal.

Print Head Technology:

Look for printers with advanced print head technology that can spread the sublimation ink evenly and correctly. This will make prints that are bright and full of detail.

ICC Profiles:

Check to see if the printer maker offers ICC profiles for sublimation ink. This can help make the printing process more accurate and vivid.

Related Post: How to Sublimate on Leather

How to Set Up Your Printer for Sublimation?

To get the best results when sublimating on stainless steel, we need to make sure that the printer settings are compatible with sublimation ink and that the prints are clear and bright.

Controlling the sublimation temperature and keeping the printer in good shape are two important parts of sublimation on stainless steel. These are some important printer choices to think about:

| Printer Settings | Description |

| Print Quality | Select the highest print quality setting to ensure sharp and detailed prints. |

| Heat Settings | Adjust the heat settings on your printer to match the recommended sublimation temperature for the stainless steel substrate. |

| Paper Type | Set the paper type to “sublimation paper” or “transfer paper” for optimal ink transfer. |

| Color Management | Use the appropriate color profile for sublimation printing to ensure accurate color reproduction. |

The Best Ways to Sublimate On Stainless Steel:

For sublimation to work on stainless steel, making sure the surface is properly prepared is one of the most important things. There shouldn’t be any dirt, oil, or other things on the surface of the stainless steel. It should be clean and shiny. When sublimating on stainless steel, here are some of the best things to do:

Clean the surface. To get rid of any dirt or grease, use a light detergent or cleaner made just for stainless steel. Rinse well and dry with a cloth that doesn’t have lint on it.

Surface Polishing:

To get rid of any scratches or other flaws on the surface, use a stainless steel shine. For a smooth and even sublimation copy, do this.

Put on a Coating:

If you want better sublimation effects, you might want to use a coating made especially for stainless steel. This layer will help the sublimation ink stick better and make the colors look more vivid.

Use the Right Method For Sublimation Transfer:

Stainless steel can be sublimated in some different ways, including using a heat press or a vacuum. Pick the method that works best for you and make sure to follow the maker’s directions for the best results.

Related Post: Sublimation On Glass

Preparing the Stainless Steel Surface for Sublimation:

To get the stainless steel surface ready for sublimation, you should first clean it very well with a mild cleaner or soap made just for stainless steel.

This is a very important step because any dirt, oils, or leftovers on the surface can stop the sublimation process and make the image transfer bad. Rinse the surface with clean water and dry it completely to make sure there is no more water on it.

Next, it’s important to think about the stainless steel’s sublimation temperature. The sublimation temperatures for different types of stainless steel alloys can change, which can affect how well the sublimation process works.

It is suggested to look at the manufacturer’s instructions or do a test run to find the best sublimation temperature for the stainless steel being used.

Also, the different finishes on stainless steel can affect sublimation. Most of the time, smooth, polished finishes work better because they give the dye a more even surface to stick to.

There may be differences in color and picture clarity when you use textured or brushed finishes. To get the result you want, try out different styles and make changes to the sublimation process as needed.

How to Fix Common Sublimation Problems on Stainless Steel:

Now, let’s talk about some problems that often happen when sublimating on stainless steel.

Uneven color spread is a problem that comes up a lot. Some parts of the design may look darker or lighter than others.

Images that are fuzzy or distorted are another issue that can make things less clear and detailed.

Lastly, the pattern may peel or flake off the surface if the coating doesn’t stick well.

These problems can be annoying, but they can be fixed properly with the right troubleshooting methods.

An Uneven Distribution of Colors:

When sublimating on polished steel, we might have trouble with the colors not spreading out evenly. This could happen for several reasons, such as color fading or weather needs. To figure out what’s wrong, try the following:

Heat Not Being Spread Evenly:

Make sure the heat press is spreading heat evenly across the stainless steel surface. Heat that isn’t spread out evenly can make colors look different.

Not Enough Pressure:

Make sure the stainless steel base is under even pressure by adjusting the heat press’s pressure settings. Uneven evaporation can happen when there isn’t enough pressure.

Prepare the Substrate:

Clean and prepare the stainless steel surface correctly before sublimation. Any grease or residue on the surface can make it harder for the color to penetrate and spread evenly.

Quality of Transfer Paper:

Make sure you use high-quality transfer paper that is made to be sublimated on stainless steel. Paper that isn’t very good might not transfer colors equally.

Image Distortion or Blurriness:

When sublimating on stainless steel, we can fix the problem of pictures that are blurry or distorted by making sure the artwork is properly aligned and using high-resolution artwork.

Low quality is a common reason why pictures are blurry or skewed. If the artwork’s resolution is too low, the picture may look pixelated or fuzzy when it is transferred to stainless steel. It is important to use high-resolution art, ideally with a sharpness of at least 300 dpi, to avoid this.

Sublimating on curved stainless steel surfaces is another thing that can make pictures blurry or distorted. Because the surface is curved, the image may stretch or warp during the sublimation process, which will make the end print look bad.

To fix this problem, you should use heat tape or glue to stick the transfer paper tightly to the curved surface. This will make sure that the heat is spread evenly and keep the picture from warping.

To fix common problems when sublimating on stainless steel, one issue that can come up is that the layer might not stick properly. This happens when the sublimated ink doesn’t stick to the stainless steel surface properly, making a picture that isn’t very good and doesn’t last long.

Several adhesion methods can be used to solve this problem:

- Putting a primer or adhesion booster on the stainless steel surface first will help the ink stick better.

- During the sublimation process, increasing the pressure and stay time will help the ink stick and penetrate better.

- Using a higher temperature setting helps the ink and film stick together better.

- Putting on a clear protective covering after sublimation will make the print last longer and stick better.

If the adhesion problems don’t go away, you might want to try using different substrates, like metal or ceramic, which stick to sublimation printing better.

Some Examples of Designs That Are Sublimated On Steel:

Now that we’ve talked about sublimating on stainless steel, let’s look at some examples of different shapes that have been sublimated on this strong material.

The sublimation process is one of a kind because it can transfer vivid and detailed images onto stainless steel. The finished goods are both attractive to look at and durable.

An example of a pattern that is sublimated on stainless steel is a personalized photo plaque.

By sublimating a favorite picture onto a stainless steel plaque, you can make a lasting keepsake that you can show off at home or work. The sublimation process makes sure that the picture is pressed into the stainless steel, giving it a smooth, shiny finish.

Custom drinkware is another thing that’s made with sublimated patterns on stainless steel. The sublimation process can be used to add complex patterns, logos, or even photos to stainless steel water bottles or tumblers.

This not only makes the drinkware more unique but also makes sure that the pattern will last and not fade or get scratched.

Also, jewelry made of sublimated stainless steel has become more common over the past few years. Jewelry artists can make one-of-a-kind, eye-catching pieces by sublimating complicated patterns onto stainless steel bracelets or pendants.

Using the sublimation process, intricate patterns can be transferred onto the stainless steel. This makes jewelry that is not only beautiful to look at but also very strong.

Bottom Line: Can You Sublimate on Stainless Steel

In conclusion, sublimating on stainless steel has many advantages, such as being long-lasting and not rusting. You can get high-quality sublimated images on stainless steel if you follow the right steps and use compatible printers.

It’s important to make sure the surface is ready and to fix any usual problems that might come up during the sublimation process. By following these tips, you can make beautiful sublimated patterns on stainless steel that will last for a long time.

FAQ

Last Updated on March 19, 2025 by Muhammad Haseeb