Formlabs’ Launches New 3d Printers Form 4 and Form 4b

Discover Formlabs’ latest innovations in 3D printing with the Form 4 and Form 4B models that are setting new standards in reliability and performance.

Key takeaways

- The Form 4 incorporates a cutting-edge laser system that greatly boosts printing speed without compromising the quality of high-resolution prints, thereby improving the efficiency of 3D printing operations.

- Specifically designed for biomedical applications, the Form 4B works with biocompatible resins to create dental and medical models. This enhances the range of practical applications of 3D printing in the healthcare industry.

- User-Friendly Design: The Form 4 and Form 4B models feature enhanced user interfaces with intuitive touchscreen displays. These displays streamline the printing process, ensuring that people with different levels of expertise can easily use the printers.

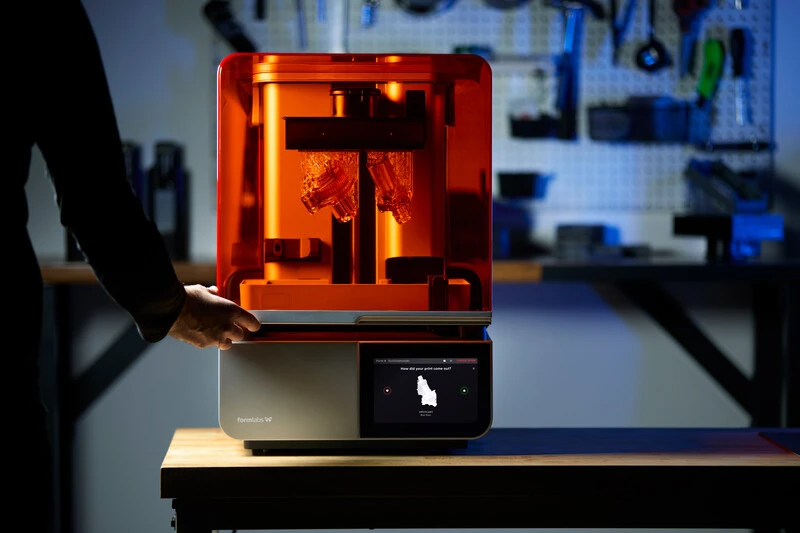

On April 23, 2024, in Boston, Massachusetts, Formlabs, a conspicuous pioneer in 3D printing innovation, will disclose two modern additions to its item range: the Form 4 and Form 4B models. These models point to growing the limits of precision and ease of utilization in additive manufacturing, subsequently expanding the availability of progressed technology for both experts and specialists.

Related Posts: Formlabs’ New Pro 3D Printers Claim 2–5x Speed By Ditching Lasers For An LCD Screen

Advancement in 3D Printing Innovation

The Form 4 and Form 4B printers are exceptional additions to Formlabs’ existing printer lineup. At the company’s base camp in Boston, the dispatch occasion demonstrated the capabilities of these new machines, emphasizing their improvements in speed, accuracy, and user-friendliness.

Improved Accuracy and Velocity:

The Form 4 improves upon its past models by integrating a progressed laser innovation that successfully pairs the printing speed while keeping up the high quality that Formlabs clients have grown used to. The printer is prepared with an advanced optical framework that produces prints with improved sharpness and exactness, making it perfect for delicate plans required in divisions such as jewelry manufacturing, dentistry, and industrial design.

Enhanced accessibility through the utilization of Form 4B:

Formlabs has now disclosed Form 4B, a specialized form created solely for biomedical use. This printer is particularly well suited for creating dental and medical models utilizing biocompatible resins. Researchers have thoroughly studied these resins to ensure their security and adequacy. The use of Form 4B has the potential to bring about a significant change in medical and dental practices. This cutting-edge innovation engages specialists to form customized instruments and solutions specifically at their offices, leading to a significant reduction in the time patients have to wait for prostheses, inserts, and other medical devices.

Interfaces and Materials Designed for Ease of Use:

Both new models showcase an enhanced, user-friendly UI that streamlines the printing procedure. The touchscreen screens offer immediate adjustments and feedback, facilitating the attainment of flawless prints for both beginners and experienced individuals.

In addition, Formlabs has broadened its selection of exclusive resins, providing new substances that address particular requirements of certain industries, such as the capacity to withstand high temperatures and improved strength.

Environmental Considerations:

The new printers prioritize sustainability by focusing on energy efficiency and using recyclable components, in line with current environmental responsibility objectives.

Expanded Material Options:

Formlabs has increased its selection of exclusive resins to encompass a wider variety of materials designed to meet specific industrial requirements, such as increased resilience to high temperatures and improved strength for more long-lasting applications.

Related Posts: A 3D Printer Used By Microsoft, Ford, and NASA Is Now Commercially Available — Here’s What It Can Do

Dedication to Sustainability

Formlabs also emphasized their dedication to sustainability during the launch. Both Form 4 and Form 4B are engineered to enhance energy efficiency and incorporate recyclable components, exemplifying the technology manufacturing industry’s pioneering shift towards more environmentally friendly production methods.

Effects on Industries

The implementation of Form 4 and Form 4B is balanced to bring almost a significant and positive alter in multiple businesses. Engineers and designers can benefit from the improved exactness and proficiency, because it permits for faster and more precise prototyping.

This has the potential to decrease the time required to bring innovative goods to the market. Form 4B’s capacity to manufacture biocompatible materials internally would expedite patient treatment by providing customized solutions, hence enhancing outcomes and patient contentment in the healthcare sector.

Related Posts: Formlabs says new 3D printer ‘rivals injection molding

What are the future plans for Formlabs?

Formlabs is determined to broaden its presence in other industries that prioritize precision and customization as it continues to innovate. Formlabs strives to continuously offer state-of-the-art solutions that cater to the changing requirements of its varied customer base, utilizing advancements in materials science and printer technology.

Conclusion:

The introduction of Form 4 and Form 4B is a noteworthy achievement in the field of 3D printing, establishing higher benchmarks for potential accomplishments in diverse professional and creative pursuits. As Formlabs continues to advance its technology, the possibility of 3D printing transforming industries and everyday life appears to be more attainable.

Last Updated on April 26, 2024 by Muhammad Haseeb