Tape Marks on Sublimation Tumbler

Do you want to know why there are tape marks on sublimation tumbler? All of the information you require is provided. Read on.

If you have never used sublimation before, you may get tape marks on the bottle. If you know how to correct the sublimation process, this problem will be easy to fix.

That being said, why are you seeing tape marks on the sublimation tumbler?

Tape markings may result from improperly applying heat-resistant tape or its poor quality throughout the sublimation procedure onto the tumbler. Additionally, incorrect management of temperature and time can result in this unsightly surface residue. It is recommended to utilize low-tack sublimation adhesive and apply the appropriate amount of heat and time; otherwise, the entire process must be repeated.

We talked about some ways to keep your sublimation mug from getting tape marks. Read this whole article to get a better idea of what it’s about.

Related Post: Is Sublimation Ink Toxic?

Key Takeaways:

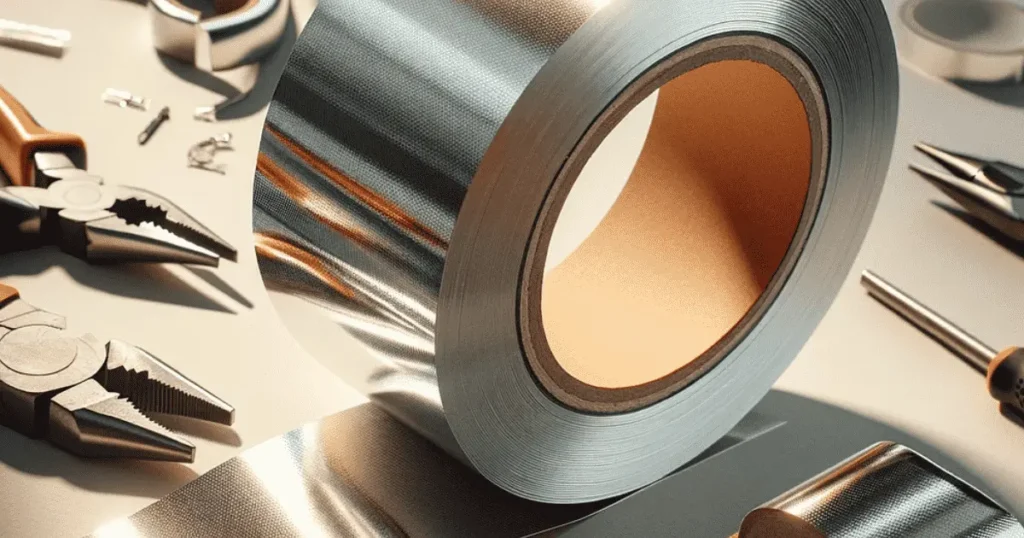

- Choose good heat-resistant tape designed for sublimation to avoid sticky residues and burns.

- Set the right temperature and time during the sublimation process to prevent tape marks. Optimal settings usually range between 380-400°F and 45-60 seconds.

- Apply tape carefully and avoid stretching it or applying too much pressure to ensure a smooth finish without marks.

- Use fresh sheets for each pressing cycle to prevent adhesive buildup, which can cause marks.

- Place protective sheets like Teflon or parchment paper over the tumbler to create a barrier and avoid tape residue.

Related Post: Why is my Shrink Wrap Melting Sublimation

Understanding Tape Marks on Sublimation Tumbler:

Problems during the transfer process are often what cause sublimation tape leaving marks on tumbler, those annoying spots that always seem to show up when you least expect them to. They’re the people you don’t want at your sublimation party because they ruin the quality and look of your finished tumbler.

They are more than just a bother. Another thing that can make a good sublimation tumbler less than perfect is a single tape mark. These marks can show up as yellow residue or as burns that get in the way of your intricate drawings and bright colors.

What are Tape Marks?

What do “tape marks” mean? Simply put, they are the sticky marks or burns that are left on your glass when the heat-resistant tape doesn’t work right during the sublimation process. They always stand out like that person who shows up at a party without being asked.

There are flaws in the finished product called tape marks that can make it look less than perfect. They can ruin the smooth, shiny finish that makes sublimation tumblers so appealing.

What Causes Tape Lines on Sublimation Tumbler?

Understanding why tape lines happen is the first step in getting rid of them, as with any problem. It’s not just luck or wishful thought; you have to understand the science behind it.

Most of the time, heat and time during sublimation soften the tape glue, leaving heat tape marks on the tumbler. It could also be because you used too much tape, which can lead to ghosting and spots if you don’t use it right. In some cases, the lines that heat tape leaves behind could be a cause of these problems.

When you’re about to cover your tumbler in tape, know that less is more.

Related Post: Can You Use an Iron for Sublimation?

Reasons Why Sublimation Tumblers Often Have Tape Marks:

Just knowing why there are tape marks isn’t enough; we need to get to the bottom of the problem. This means looking into the most common reasons why tape marks show up on sublimation tumblers in great detail.

Many things can cause tape marks to show up, ranging from bad tape to wrong temperature and time choices. Let’s look at these bad guys one by one, shall we?

Poor Quality Heat-Resistant Tape:

The quality of the heat-resistant tape you use can have a big effect on how well your sublimation printing turns out. Sticking something together with cheap tape is like trying to fix a leak with gum—it won’t work.

Heat-resistant tape that isn’t very good can melt or leave a sticky film during the sublimation process, which can cause the feared sublimation tape marks. Making sure you use good sublimation tape that can handle the high temperatures needed to press sublimation tape is very important.

Incorrect Settings for Time and Temperature:

The trick to making the perfect sublimation tumblers is to set the temperature and time correctly. During sublimation, if you mess up the temperature and time, the tape could fail and leave marks or a sticky film on the tumbler.

To make sure the tape can stand up to the heat and not leave any marks, it’s important to set the time and temperature correctly. If you leave it in the oven for too long or too hot, your beautiful cake will get burned.

Incompatible Materials:

Have you ever tried to use a magnet on a bottle? Do you agree that it doesn’t work? The idea behind sublimation tapes and tumblers is the same. Tape marks can show up if you use tapes with strong glue or thin materials that can’t handle the heat of sublimation. It’s all about getting along.

Like a dance that is perfectly timed, the tape, tumbler, and heat must all work together to get a perfect finish.

Incorrect Application Techniques:

The way you put the tape on the bottle can also change how the sublimation process turns out. It’s important to use the tape correctly so that the finish is smooth and there are no tape marks on the tumbler.

Tape lines can happen if you don’t use the right methods, like stretching the tape or putting too much pressure on it. If you were wrapping a present, you wouldn’t just throw the tape on without thinking, would you? When you tape your sublimation mug, you should be just as careful and precise.

Using the Same Sheet For Each Pressing Cycle:

If the same sheet is used over and over to press the tape, it might lose its ability to stick. To keep the adhesive from building up on the tumbler, the tape should be taken off between pressing rounds.

During later pressing rounds, the tape might not stick as well because of this. Because of this, the tape might move or tear while being pressed, which could leave a mark on the base when it is removed.

Related Post: Can you Sublimate Over Sublimation?

Best Practices for Avoiding Tape Marks:

Now that we’ve talked about What causes tape marks on sublimation tumblers?, it’s time to talk about how to avoid them. As the old saying goes, prevention is better than cure. There are a few good habits you can use to keep your sublimation tumblers from getting tape marks.

Let’s look at the best ways to keep those annoying tape marks from ruining your perfect sublimation print, from picking high-quality tape to making sure the temperature and time settings are just right.

Choosing Good Heat-Resistant Tape:

The most important thing is to choose good heat-resistant tape. If you skip this step, it won’t help you in the long run, especially if you’re using heat tape.

High-quality heat-resistant tape is made to handle heat, so it won’t melt or leave a sticky film even when the sublimation process is very hot. The investment pays off with sublimation tumblers that are perfect and don’t have any marks on them.

Improving Time and Temperature Configurations:

You can’t just pick any number for the temperature and time settings. For the sublimation process you are using, they need to be exact and made just for you.

Temperatures between 380 and 400 degrees Fahrenheit are best, and the time should be between 45 and 60 seconds. If you stray too far from these limits, tape marks may appear. Before you start the sublimation process, you should always check your settings again.

Correctly Applying Tape:

Another important thing to do to avoid tape marks is to use the tape properly. It’s not as simple as putting on the tape and calling it a day. There’s a reason for everything.

These steps will help you put heat-resistant tape on sublimation tumblers:

- Take a long piece of tape and start.

- On the other side of the seam, put it in the middle.

- Make sure it sticks well by wrapping it around the glass very tightly.

- To keep the tape from getting marks, don’t stretch it or put too much pressure on it.

Protective Sheets:

Last but not least, put down Teflon, parchment paper, paper tapes, or other protected sheets to avoid getting tape marks. These safety sheets put up a wall between the masking tape and the tumbler so that any sticky residue doesn’t leave marks.

To sublimate tumblers, put a sheet of transfer paper, make sure it’s sublimation paper, on top of your picture, and press it down against the tumbler. This easy step can help a lot to keep tape marks from showing up.

Related Post: Can You Put Epoxy Over Sublimation

How to Remove Heat Tape Marks from Sublimation Tumbler-Effective Ways:

Even though we try really hard, tape lines do get on our sublimation tumblers from time to time. Don’t worry, though—there are several good ways to get rid of these annoying marks.

There are some ways to get the tape marks off of our sublimation tumblers, such as using chemical removers, heat treatment, or mechanical removal.

Detergents and Chemicals:

If you want to get rid of tape marks, chemical removers like rubbing alcohol or glue removers can be very helpful. Their job is to break down the tape’s sticky film, making it easy to wipe off.

Still, care must be taken when using these chemical removers; they should only be used rarely and gently so as not to damage the tumbler’s surface. Also, don’t forget to rinse well after each use to get rid of any leftover dirt.

Heating Method:

Putting something under heat, like with a heat press, is another good way to eliminate tape marks. When you put high heat on the tumbler, the tape’s sticky residue softens. This makes it easier to peel off or wipe off.

First, use a heat gun to heat the tumbler for about three minutes. Then, slowly peel off the tape. Make sure you do this on a surface that can handle heat, and wait until the jar is cool before you try to get the tape off of it.

Mechanical Removal:

The last way to get rid of tape lines is to use mechanical methods, like scraping or sanding. To keep the surface of the tumbler from getting damaged, these ways should only be used with care.

If you want to get rid of tape marks on your tumbler, do these things:

- Rub alcohol should be put on a soft cloth.

- Be careful as you dab and rub the damaged areas.

- The tape marks will come off safely and effectively, and your tumbler will look brand new again.

Related Post: How Long Does Screen Print Last

Which Tapes Should I Use for Mark-Free Sublimation?

Heat-resistant tape is created to withstand the heat of the press. If you wish to prevent the presence of markings caused by sublimation tape that is of poor quality, it is essential to choose a high-quality product that is specifically designed for sublimation printing. It is a preferred option for sublimation printing due to its ability to avoid melting or leaving any adhesive residue on the substrate. The following are a few of the most popular:

| Product Name | Description |

| 3M High-Temperature Flue Tape | It works great for sublimation printing because it can handle high heat. It’s easy to use, and the glue residue will not damage your material. |

| Lichamp Tape for High Temperatures | The tough polyimide film that this tape is made of can stand up to temperatures of up to 500°F. You can use it for sublimation printing, and the glue is strong enough that it won’t leave any marks on your material. |

| Yubbaex Heat Resistance Tape | This tape is made from PET film and has silicone glue that can handle heat up to 482°F. It’s great for sublimation printing because it won’t leave any film on the surface. |

| Fiberglass Fabric Tape Coated with PTFE | Fabric made of fiberglass is used to make PTFE-coated fiberglass fabric tape, which can handle a lot of heat. It works great for sublimation printing because it is easy to use and won’t harm the material. |

Before you buy something, you should also read the product description and customer reviews to make sure you’re getting the right thing for your needs.

Related Post: Can you Sublimate on a Baseball

Bottom Line:

In conclusion, tape lines are common with sublimation tumblers, but they can be avoided and taken off. There are several things you can do to avoid getting these annoying marks, such as using high-quality heat-resistant tape and making sure the temperature and time settings are perfect.

Chemical removers, heat treatment, and mechanical removal are all effective ways to get rid of tape lines and get your sublimation tumblers back to their original, mark-free glory. Don’t let tape marks ruin your sublimation experience. If you know what you’re doing and how to do it right, you can make perfect sublimation tumblers every time.

FAQ

Last Updated on June 8, 2024 by Muhammad Haseeb