Bambu Lab Launches Multicolor 3D Printer for Under $500

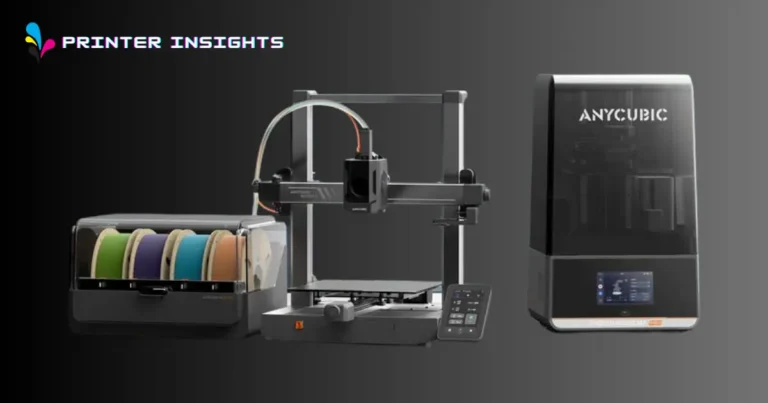

Bambu Lab, a manufacturer of desktop 3D printers, has introduced the AMS lite and A1 mini, their most recent FDM multicolor 3D printer models.

This brand-new desktop 3D printer can print in four colors, is automatically calibrated, compensates for variable flow rates, cancels out motor noise, and has a build space of 180x180x180 mm3.

This is an entry-level product from Bambu Lab. The company says that its newest 3D printer will give newbies high-end, cutting-edge features, making multi-color 3D printing easier for more people to do.

You can now pre-order the A1 mini and AMS lite set through the Bambu Lab online shop. The first batch of goods will be sent out from local stores around the middle of October.

Each retail package of the A1 mini and AMS lite comes with a unique mystery box and a set of Bambu filament colors. People should use the Bambu Handy App to read the QR code on the mystery box to get more information, says Bambu Lab.

Read: Best Sublimation Printers

Key Features of the New A1 Mini:

The A1 small comes already put together, squared, and tuned. So, Bambu Lab says the new 3D printer works right out of the box and doesn’t need to be set up or adjusted in any way.

The A1 small does all of the calibrations. The Z-offset, bed level, and X and Y-axis vibration resonance are all checked and set instantly before each 3D print job. On top of that, the A1 Mini has a new nozzle pressure monitor that sets the flow dynamics automatically.

The newest 3D printer from Bambu also has a brand-new tablet interface that is said to be easy to use. It is said that the UI’s IPS touchscreen makes operation as smooth as a smartphone.

The system walks users through all the steps of 3D printing and helps them with any HMS system problems. In addition, the A1 mini can now use the new MakerWorld platform to load pre-set 3mf files. With just one click, users can begin 3D printing.

With a Quick Swap Hotend, the A1 small is also easy to keep up. This only comes with one clip, which makes it easy to remove the hot end. The whole process of swapping the hot end can be done in less than 30 seconds, and there is no need for an electrical connector.

The latest 3D printer from Bambu Lab was also made to look good, with a soft color scheme and a clean CMF design. In line with its name, the A1 mini has a small body, measuring 347 mm3 x 315 mm3 x 365 mm3. The A1 mini can fit in a variety of workspaces because it only takes up a little more room than an A4 sheet of paper.

The new A1 small also has Active Motor Noise Cancellation technology built in. The company Bambu Lab says this successfully lowers motor movement noise, making 3D printing quieter.

When the A1 mini is turned on for the first time, it will go through a motor testing process to make sure that the vibrations of the 3D printer’s motors are set correctly.

The A1 mini’s all-metal tracks and linear bearings make it very reliable, which is another thing that makes it stand out. All-metal tracks make V-wheels more rigid and accurate than regular plastic ones.

The A1 mini’s structure also needs less tuning and upkeep, which makes it easier for beginners to use.

The drive system of the A1 mini is covered by a cover, which helps keep accidents and outside particles from happening. The Z-axis cover also keeps the user’s hands from getting dirty on the screw rod.

The newest product from Bambu Lab is said to have the “most advanced” filament monitoring tools on the market.

In contrast to most 3D printers that use filament runout sensors to identify filament presence, the A1 mini checks for filament presence, speeds and odometry, tension above the extruder, and pressure under the extruder.

This lets people see when the filament runs out, gets tangled on the spool, or slips on the printer. Also, 3D prints are stopped immediately when a problem is found, and the HMS system can figure out exactly what the problem is.

According to its creators, the Bambu HMS code system is very easy to use. By looking up a specific code, problems can be quickly and easily identified.

Also, all the parts that need to be replaced are flexible and simple to swap out, which makes part replacement easy and cheap.

It’s also said that the new 3D printer is all about making fast prints. In fact, the A1 small can 3D print at speeds of up to 500 mm/s and as fast as 10,000 mm/s2.

At the start of every 3D print job, vibration testing is done for both the X and Y axes. This makes sure that high-speed 3D printing is accurate.

Most 3D printers on the market use fixed numbers that don’t change while the 3D printing is going on.

The A1 mini, on the other hand, adjusts the numbers before each 3D print to account for the temperature and tension of the 3D printer. At the hot end, there is also an Eddy Current monitor that measures the extrusion pressure before 3D printing.

This adjusts the flow rate of extrusion so that it stays fixed during the 3D printing process.

Multi-color 3D Printing With AMS Lite:

The AMS lite is a new and improved form of the original AMS. It makes 3D printing with multiple materials simple and easy. This new AMS has fewer parts than the old one and all of the parts that need to be maintained are visible.

This makes it more reliable and easier to maintain. When it comes to the PTFE tube, Bambu Lab says it is “super easy” to take out a thread that has broken.

AMS lite also has Bambu RFID readers added, which allow the automated synchronization of the filaments. So, AMS lite can automatically find and sync the different types of Bambu filament with Bambu Studio. This lets the 3D printer setup be optimized for the best results.

Bambu Lab told the 3D Printing Industry that AMS lite works with the A1 line of 3D printers and that the original AMS works with Bambu Lab X1 and P1 3D printers.

When it comes to materials, Bambu Lab says that the AMS lite can be used with the same ones as the original AMS. Because of this, the AMS lite can use different types and colors of filament.

Flexible filaments like TPU and TPE, and absorbing filaments like PVA, should not be used with the AMS lit, says Bambu Lab.

Pricing and Technical Specifications

The AMS lite costs $249 USD and the A1 small costs $299 USD. You can also buy both items together for $459 USD as the A1 small and AMS lite combo.

| Build up Volume | 180x180x180 mm3 |

| Chassis | Aluminum extruded with steel |

| Hot End | All-Metal |

| Extruder Gears | Steel |

| Nozzle | Stainless-Steel |

| Max Hot End Temperature | 300℃ |

| Nozzle Diameter (Included) | 0.4 mm |

| Nozzle Diameter (Optional) | 0.2 mm, 0.6 mm, 0.8 mm |

| Cutter for Filament | Yes |

| Filament Diameter | 1.75 mm |

| Compatible Build Plate | Bambu Textured PEI PlateBambu Smooth PEI Plate |

| Build Plate Maximum Temperature | 80℃ |

| Max Speed of Tool Head | 500 mm/s |

| Maximum Tool Head Acceleration | 10 m/s2 |

| Max Hot End Flow | 28 mm2/s @ ABS (Model: 150×150 mm single wall; Material: Bambu ABS; Temperature: 280℃ |

| Ideal Supported Filaments | PLA, PETG, PC, PA, PVA |

| Observation Camera Filament Run Out Sensor | Low Rate Camera (up to 1080P)Time Lapse Supported Yes |

| Filament Odometry | Yes |

| Power Loss Recover | Yes |

| Filament Tangle Sensor | Yes |

| Physical Dimensions | 347x315x365 mm3 |

| Weight | 5.5 kg |

| Input Voltage | 100-240 VAC, 50/60 Hz |

| Display | 2.4 inches 320×240 IPS Touch Screen |

| Connectivity | Wi-Fi, Bambu-Bus |

| Storage | Micro SD Card |

| Control Interface | Touch Screen, APP, PC Application |

| Motion Control | Dual-Core Cortex M4 |

| Slicer | Some third-party part slicers, like Superslicer, Prusaslicer, and Cura, can export standard Gcode and work with Bambu Studio. However, some advanced features may not be enabled. |

| Slicer Supported OS | MacOS, Windows |

Last Updated on April 14, 2024 by Muhammad Haseeb